Siemens Step 5 V7.2 Software

Oct 12, 2017 Java Project Tutorial - Make Login and Register Form Step by Step Using NetBeans And MySQL Database - Duration: 3:43:32. 1BestCsharp blog 5,439,635 views. How do I register Express Accounts? If you received a 12 digit activation code, you will need to activate it using the following steps to get your registration code. Download one of NCH Software's many free software programs in the audio, video, business, graphics, computer utility and dictation space for Windows or Mac. Nch express accounts plus.

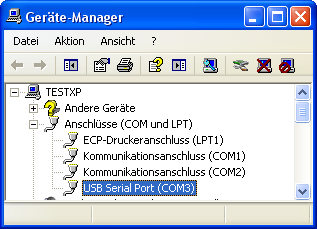

STEP 5 V7.2 will execute under Windows XP. This support ensures that the optional packages (such as GRAPH 5/II), as well as the COM packages that can be started via STEP 5, will execute under Windows XP. Note: The SIMATIC S7 Industrial Software will support Windows XP by the end of 2002. Support of the new USB Prommer.

Nie Hau Ma?I would suggest that you log on to www.IBHsoftec.de and have a look at their S5 for Windows software package. It is reliable and much cheaper than the Siemens official software. For an S5-100U it will do the job very nicely, I would not recommend this software for any PLC with Intelligent Modules, since it does not have the necessary Special Functions, but, for basic S5 processors it has been very useful to me.

Since you are upgrading to S7, they also do S7 software and a conversion application from S5 to S7. This also works reasonably well.Good Luck,Jimmy McLachlan. On searching again, I didn't find back the V6.0 manual. All I'm finding now is:Working with S5-DOS/ST (V6.6 - ) (Version 6.6 (5/ST V7.0 (5/ST V7.1 (STEP 5 V7.2 (found these results browsing the STEP 5 Manuals (part of the Siemens site. At the bottom of that page it mentions '© Siemens AG, 1998, 2004', so I think it's unlikely to find older manuals at the Siemens site.Hope this helps.

Intuitive and efficient engineering – from the microcontroller to the PC-based controllerWith SIMATIC, users rely on an integrated engineering environment. Efficient software supports users over the entire life cycle of the machine or plant – from the planning and design stages, through configuring and programming, all the way to commissioning, operation and upgrading. With its integration capability and harmonized interfaces, SIMATIC software permits a high degree of data consistency – throughout the entire engineering process.

Siemens S7 Software Free Download

Siemens Step 5 Download

SIMATIC STEP 7 (TIA Portal) continues the success story of SIMATIC STEP 7.With SIMATIC STEP 7 (TIA Portal) users configure, program, test and diagnose the basic, advanced and distributed controllers of each generation, whether it is PLC- or PC-based, incl. Software controllers.With its vast array of easy-to-use functions, the STEP 7 software significantly boosts efficiency in all of your automation tasks. Whether for configuring hardware, establishing communications, programming, testing, commissioning and service, documentation and archiving, or operational and/or diagnostic functions, the software sets the benchmark in its field. SIMATIC STEP 7 is the world's best known and most widely used engineering software in industrial automation. SIMATIC STEP 7 V5.6 is the proven programming software for the controller families S7-300, S7-400, C7 and WinAC.Information on STEP 7 VersionsFor programming controllers of the latest generation S7-1200, S7-1500, ET 200SP CPU and S7-1500 Software Controller you need STEP 7 (TIA Portal) Engineering Software.Of course you can program the S7-300, S7-400 and SIMATIC WinAC controllers with this software as well.STEP 7 Professional 2017 includes the STEP 7 V5.6 basic software and additional editors. New installations of STEP 7 Professional 2017 are only available as combo licenses together with STEP 7 Professional V15 (TIA Portal).

This combo license for both platforms enables you to work using both STEP 7 (TIA Portal) as well as traditional engineering software.System innovation and migrationHigher productivity, efficiency and availability through modernizationTo stay competitive, machines and facilities have to be continually adapted to the latest requirements.If your automation system is no longer up to date, it is time for a modernization.